Material: aluminum alloy + soft rubber

Data format: STP/IGS/X.T/PRO

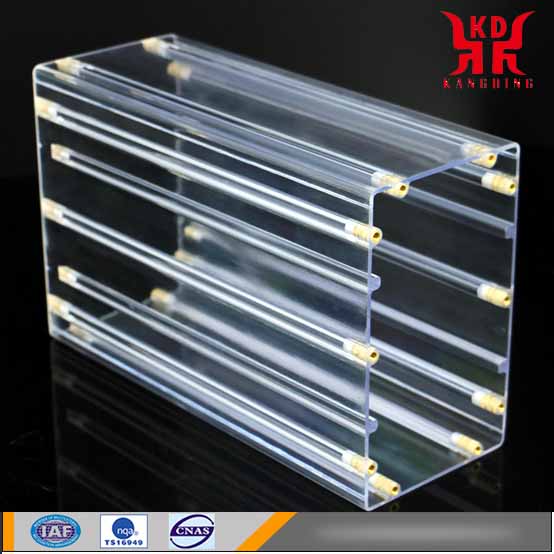

Category: Customization of military product prototypes

Product introduction: The product adopts aluminum alloy and soft rubber encapsulation, which is the configuration that most military communication mobile phones need to be used for earthquake resistance.

Prototype can check the design

The prototype is not only visible, but also touchable. It can intuitively reflect the designer's creativity in the form of objects. It avoids the disadvantage of "drawing to look good but processing to make it look bad". Therefore, prototyping is indispensable in the process of new product development and product shape deliberation.

Prototype can verify the structural design

Because the prototype is assembleable, it can intuitively reflect the reasonableness of the structure and the ease of installation. It is convenient to find and solve problems early.

Avoid the risks of direct mold manufacturing

Because the cost of mold manufacturing is generally high, relatively large molds are worth hundreds of thousands or even millions. If unreasonable structure or other problems are found in the process of making the mold, the loss can be imagined. Prototyping can avoid this loss and reduce mold risk.

Product launch ahead of schedule

Due to the advanced nature of prototype production, you can use the prototype to promote the product before the mold is made, and even the pre-sales and production preparations to occupy the market as soon as possible.

Data format: STP/IGS/X.T/PRO

Category: Customization of military product prototypes

Product introduction: The product adopts aluminum alloy and soft rubber encapsulation, which is the configuration that most military communication mobile phones need to be used for earthquake resistance.

Prototype can check the design

The prototype is not only visible, but also touchable. It can intuitively reflect the designer's creativity in the form of objects. It avoids the disadvantage of "drawing to look good but processing to make it look bad". Therefore, prototyping is indispensable in the process of new product development and product shape deliberation.

Prototype can verify the structural design

Because the prototype is assembleable, it can intuitively reflect the reasonableness of the structure and the ease of installation. It is convenient to find and solve problems early.

Avoid the risks of direct mold manufacturing

Because the cost of mold manufacturing is generally high, relatively large molds are worth hundreds of thousands or even millions. If unreasonable structure or other problems are found in the process of making the mold, the loss can be imagined. Prototyping can avoid this loss and reduce mold risk.

Product launch ahead of schedule

Due to the advanced nature of prototype production, you can use the prototype to promote the product before the mold is made, and even the pre-sales and production preparations to occupy the market as soon as possible.

Special paint for security equipment

The surface of the aluminum alloy prototype is sprayed with oil to achieve the anti-slip friction effect and the insulation function

Glue treatment of security equipment

A whole prototype is embedded in the mold, and then encapsulated to form a soft plastic shape. Structure diagram of internal security equipment

Silicone buckle for security equipment

The hardness is in accordance with the hardness requirement of 70℃±5℃ required by customers

Sealing and waterproof ring of security equipment

Sealed with silica gel, which meets the requirements of customers for daily waterproofing