Product Categories

Product Tags

Characteristics and main uses of aluminum profiles

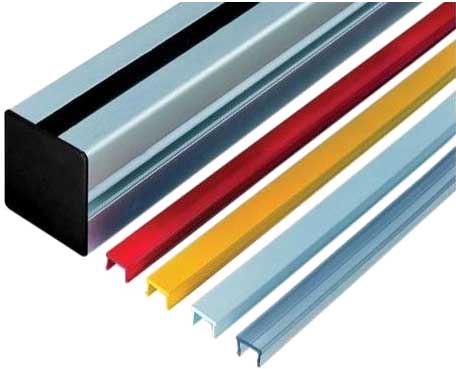

Aluminum profiles are classified by use: Aluminum profiles for construction: architectural aluminum profiles mainly include aluminum profiles for doors and windows and aluminum profiles for curtain walls;

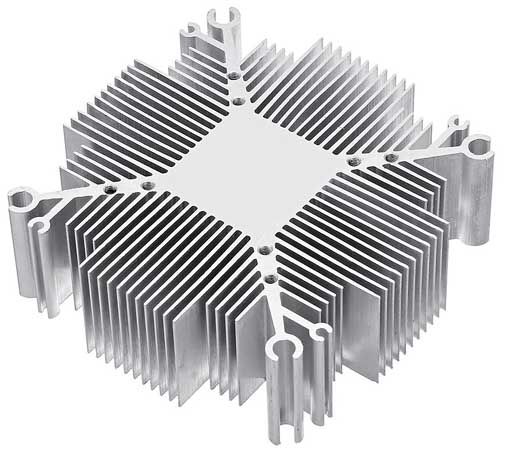

Radiator aluminum profile: mainly used for heat dissipation of various power electronic equipment, LED lighting, and computer digital products.

General industrial aluminum profile refers to:

Mainly used in industrial production and manufacturing, such as assembly line conveyor belts, hoists, glue dispensers, testing equipment, shelves, etc., electronic machinery industry and clean rooms, etc.

Aluminum profiles are classified by use: Aluminum profiles for construction: architectural aluminum profiles mainly include aluminum profiles for doors and windows and aluminum profiles for curtain walls;

Radiator aluminum profile: mainly used for heat dissipation of various power electronic equipment, LED lighting, and computer digital products.

General industrial aluminum profile refers to:

Mainly used in industrial production and manufacturing, such as assembly line conveyor belts, hoists, glue dispensers, testing equipment, shelves, etc., electronic machinery industry and clean rooms, etc.

Aluminum profiles for auto parts: Mainly used for auto parts, connectors, etc. Furniture aluminum profiles are mainly used for furniture decoration frames, table and chair supports, etc.

Solar photovoltaic profiles include: Solar aluminum frame, solar photovoltaic bracket, solar photovoltaic tile fasteners, etc.

Aluminum alloy profiles for rail vehicle structure: Mainly used in rail vehicle body manufacturing. Aluminum alloy profiles have the characteristics of light weight, good formability, high strength, corrosion resistance, and recyclability. In recent years, aluminum and aluminum alloys have been widely used in the field of rail vehicles.

Aluminum profile characteristics

Corrosion resistance of aluminum profile

The density of aluminum profile is only 2.7g/cm3, which is about 1/3 of the density of steel, copper or brass (7.83g/cm3, 8.93g/cm3, respectively). In most environmental conditions, including air, water (or salt water), petrochemicals and many chemical systems, aluminum can show excellent corrosion resistance.

Good conductivity

Aluminum profile is often selected because of its excellent electrical conductivity. On the basis of equal weight, the conductivity of aluminum profile is close to 1/2 of copper.

High thermal conductivity

The thermal conductivity of aluminum alloy is about 50-60% of copper. This is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, and automobile cylinder heads and radiators.

Non-ferromagnetic

Aluminum profiles are non-ferromagnetic, which is an important feature for the electrical and electronic industries. Aluminum profiles are not spontaneously combustible, which is important for applications involving handling or contact with flammable and explosive materials.

Machinability

The workability of the aluminum profile is excellent. In various deformed aluminum alloys and cast aluminum alloys, as well as in the various states that these alloys have after being produced, the machining characteristics change considerably, which requires special machine tools or technology.

Formability

The specific tensile strength, yield strength, ductility and corresponding work hardening rate dominate the change in allowable deformation.

Recyclability

Aluminum has extremely high recyclability, and the characteristics of recycled aluminum are almost indistinguishable from primary aluminum.

Aluminum materials for electrical equipment components

1. Normal decoration use: 1080, 1070, 1050, 6063 boards, shapes

2. Powerful top base and maintenance board: 1100, 5052, 5082 board

3. Maintenance box, capacitor box: 1100, 1050 boards

4. Electric capacitors: 1085, 1070, 1050 foil

5. Variable storage battery: 1100, 1050, 1070, 5052 plate, foil

6. Bearings: 2011, 2017 rods and tubes

7. Loudspeaker frame: 1100, 5052 boards

8. Rotary knob: 2011, 5052, 5056, 6063, 6262 sticks and plates

9. Thank you for closing points: 1100, 5052 boards

10. Zaohan lamp metal heart: 3004 plate

11. Luminous metal heart: 1100 plates

12. Sheath heater: 1100, 3003, 6063 tubes

13. Conductive tubes: 1050, 3003, 6063 shapes, tubes

14. Semiconductor heat collector: 1050, 6063 plates and shapes

15. TV ground wire: 1100, 3003, 6063 tube

16. TV cabinet: 5052 boards

18.VTR tape guide: 5052, 5056, 6063, 7003 shapes, tubes

19. Magnetic square plate: 5086 plates

20. Magnetic drum: 2025, 2218, 4032 forged products

21. Radar ground wire, dish antenna: 6061, 6N01, 6063 profiles

22. Motor frame: 1050, 6063 plates and shapes

23. Revolving fold Coil: 1060, 6101 shapes, 2024, 7N01 shapes, 1060, 6101, 6061, 6063 shapes, plates, tubes

24. Cable coating: 1050 tubes and plates

25. Ventilation fan blades: 1100, 3003, 5052 plates

26. Electric cooker: 1100, 3003, 3004, 5N01 board

27. Poly cold film: 1100, 1200, 1050, 3003, 7072 board

28. Copier cylinder: 1050, 3003, 6063 tubes

(4) Aluminum profiles for machinery and packaging and unloading containers

1. Close system of optical fine machine

(1) Camera body: 5052, 5056, 6262 tube, rod

(2) Camera camera: 1100, 5N01 board

(3) Component types: 2011, 5056, 6262 rods

(4) Keyboard: 1050, 1100 boards

(5) Gears and top plates: 2014, 2017, 5083 plates

Aluminum profile for heat dissipation of LED lighting

Solar aluminum profile frame

Aluminum profiles for furniture

Aluminum profile for construction

Contact Us

Waiting for your email, we will reply you within 12 hours with valuable information you needed.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe