Product Categories

Product Tags

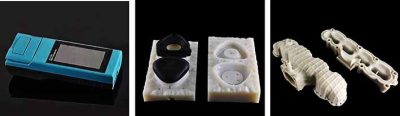

Low Volume plastic prototype processing

Low Volume processing of plastic prototypes includes: CNC machining, Silicone vacuum casting, 3D printing, silicone prototype, ABS, acrylic

Low Volume processing of plastic prototypes includes: CNC machining, Silicone vacuum casting, 3D printing, silicone prototype, ABS, acrylic

Category: Plastic prototype

Product name: rapid prototyping

Processing method: cnc processing, (Silicone vacuum casting), 3D printing

Material: abs natural color

Surface treatment: polishing and deburring, oil injection, uv

Processing cycle: 3-7 seven working days

Testing standard: 3D drawings provided by the customer

Data format: STP/IGS/X.T/PRO

Product features: smooth surface, UV, anti-fingerprint, no burr, glossy appearance, fine workmanship. High-precision processing, no mold opening, cost saving, fast delivery, and support for small batch customization

cnc machining plastic prototype: Is the customers over the 3D drawing program, split. The plastic material of the plate is processed directly through the program, and the excess part of the plastic material is removed to obtain the prototype of the product. Manual processing and surface treatment are required in the follow-up.

3D printing plastic prototype: build the prototype of the plastic object by printing layer by layer. At present, the most widely used material is plastic, and metal materials can also be 3D printed, but the price is more expensive, more expensive than the CNC processing method.

Silicone vacuum casting:Use the processing method of vacuum casting. We need to make the original version of the product first. The prototype can be made by the above two processing methods, and a silicone mold is made according to the original version.

Design of Silica Gel Vacuum Casting Compound Mould

CNC machined plastic prototype manufacturer

Small batch plastic prototype supplier

Finishing of plastic prototypes

Contact Us

Waiting for your email, we will reply you within 12 hours with valuable information you needed.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe