Product Categories

Product Tags

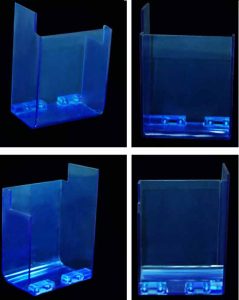

Manufacturing of acrylic prototypes

Machined, silicone vacuum overmolded PMMA prototype

In the prototype industry, acrylic, also known as PMMA, is a transparent prototype material. Acrylic prototypes are mainly made by cnc processing. Acrylic has a relatively good transparency effect, which can reach 95% of the light transmittance.

Machined, silicone vacuum overmolded PMMA prototype

In the prototype industry, acrylic, also known as PMMA, is a transparent prototype material. Acrylic prototypes are mainly made by cnc processing. Acrylic has a relatively good transparency effect, which can reach 95% of the light transmittance.

Disadvantages of acrylic prototype:

Everyone knows that glass is very brittle, and acrylic is a kind of plexiglass. Therefore, its physical properties are also very brittle, and the shortcoming of poor toughness causes the acrylic to break accidentally. In the process of prototyping, this is the focus of attention. If the machining process cannot be completed, it can only be replaced with other materials, such as PC.

Advantages of acrylic prototype:

The important thing is high transparency. After polishing, the transparency can achieve the effect of full transparency. This effect is called plexiglass in the industry, which is unmatched by PC materials. Although PC is also transparent, the effect is not as good as that of acrylic.

CNC machined acrylic prototype shell

Contact Us

Waiting for your email, we will reply you within 12 hours with valuable information you needed.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe