Product Categories

Product Tags

Non-standard OEM Small electronic turning parts

Our company customizes all kinds of precision automatic lathe processing parts for various industries, especially the electronics industry. At present, hundreds of products have been developed for many well-known companies in the world. Has rich experience in research and development.

Main materials: aluminum, copper, stainless steel, titanium, alloy, steel, iron, carbon steel, magnesium, plastic, acrylic

In addition to automatic lathes, there are auxiliary equipment: desktop lathes, drilling machines, milling machines (grooving machines), tapping machines, rolling machines, etc., which can complete more processes of automatic lathe processing parts.

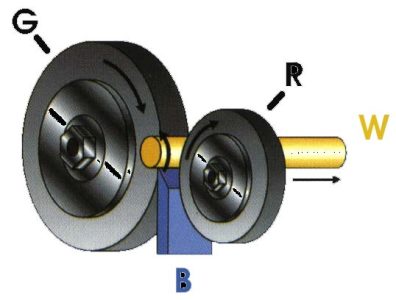

The left is a typical turning part of an automatic lathe: embedded nut used in injection molding

Small electronic turning parts | Our company customizes all kinds of precision automatic lathe processing parts for various industries, especially the electronics industry. At present, hundreds of products have been developed for many well-known companies in the world. Has rich experience in research and development. |

Non-standard stainless steel screws | Non-standard stainless steel screws, special thread turning parts, etc. |

iso ts16949 factory milled copper parts | Generally speaking, the inner hole tolerance can reach 0.02MM (if it is stainless steel or free-cutting steel products, it is 0.03). At the same time, flat-bottomed holes can be processed by hook cutters, and step holes can be drilled by forming drills (except for eccentric holes). The inner hole roughness can be up to 0.8. |

Centerless grinding of turned parts | Small turning electronic pins. Used in electronic signal connectors and connector pins. |

Oxidation blackening of iron turning parts | Non-standard turning parts: |

Contact Us

Waiting for your email, we will reply you within 12 hours with valuable information you needed.

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe