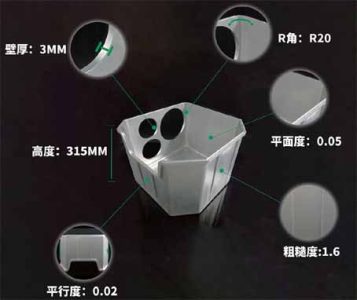

The aluminum alloy cavity is used in aerospace products. Milling parameters (difficulty): product height 315mm, internal R20, flatness 0.05, parallelism 0.02, roughness 1.6.

The aluminum cavity is a shell of an aerospace component customized for an aerospace manufacturing company. The aluminum cavity is a high-precision and difficult CNC milling cavity. The processing depth is as high as 315mm, and the accuracy requirements for parallelism and flatness are very high. Since I signed a non-disclosure agreement with the client, the details will not be described again.

Product name: Aluminum cavity used in military industry

Processing method: CNC milling of aluminum alloy cavity

Material: aluminum alloy

Surface treatment: polishing, deburring, oxidation

Processing cycle: 3-7 seven working days

Testing standard: 3D drawings provided by the customer

Data format: STP/IGS/X.T/PRO

Product features: smooth surface, high gloss, fine workmanship

Difficulties of CNC milling aluminum cavity

CNC machining of aluminum cavity used in aviation

English

English العربية

العربية 中文(漢字)

中文(漢字) Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 ಕನ್ನಡ

ಕನ್ನಡ 한국어

한국어 Português

Português Русский

Русский Slovenčina

Slovenčina Español

Español Svenska

Svenska Türkçe

Türkçe